INTRODUCING HydraTerra

Now you can get two industry-leading substrates in one superior premix! This new formulation of HydraFiber® Advanced Substrate and Sunterra® Canadian Sphagnum Peat provides reliable results for growers of all sizes.

The Ultimate Growing Media Substrate

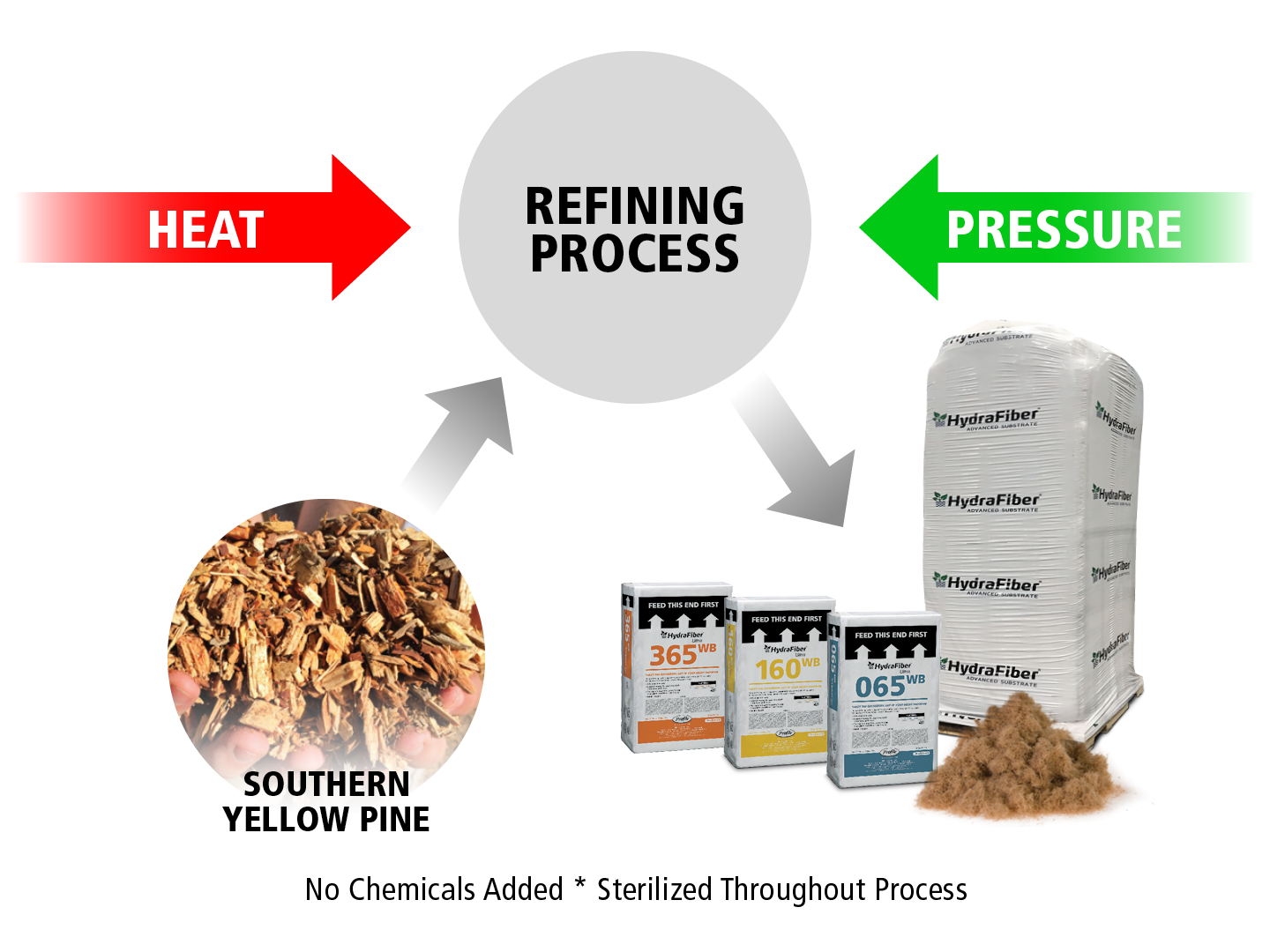

The first substantial substrate innovation in almost 45 years, HydraFiber® is an approximately 98% porous fiber substrate with extremely low bulk density. HydraFiber is manufactured with our unique Thermally Refined® process that combines wood and bark and refines them in a pressurized vessel to create singulated, small-diameter, long, thin strands with large surface area (U.S. patent 10,266,457 and patents pending). With quality control and quality assurance checks every 30 minutes during production, HydraFiber is the same 365/24/7.

The most progressive growers in the country have switched to HydraFiber because of its many advantages:

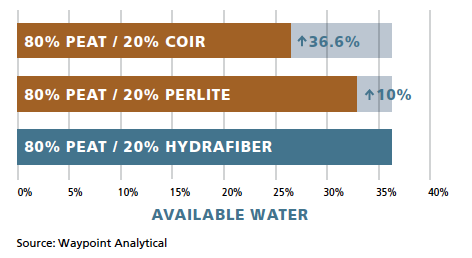

- 10% to up to 36.6% more available water to every plant due to fiber surface area up to seven times greater than peat

- Better air space and greater moisture availability lead to better root establishment and faster rooting

- No expansion with water needed

- Blends easily with other mix components

- Delivers more efficient storage per cubic yard of material than peat, bark, perlite, coir or vermiculite

- Locked-in contract pricing available

- Available unfrozen and ready to use when you want it

Request a Product Sample Kit

Start your move to better growing media by requesting a free product sample kit. Complete a request form and you can begin a seamless transformation to better margins and better plants.

Advantages

We are experts in wood refining. Take a quick tour of the process.

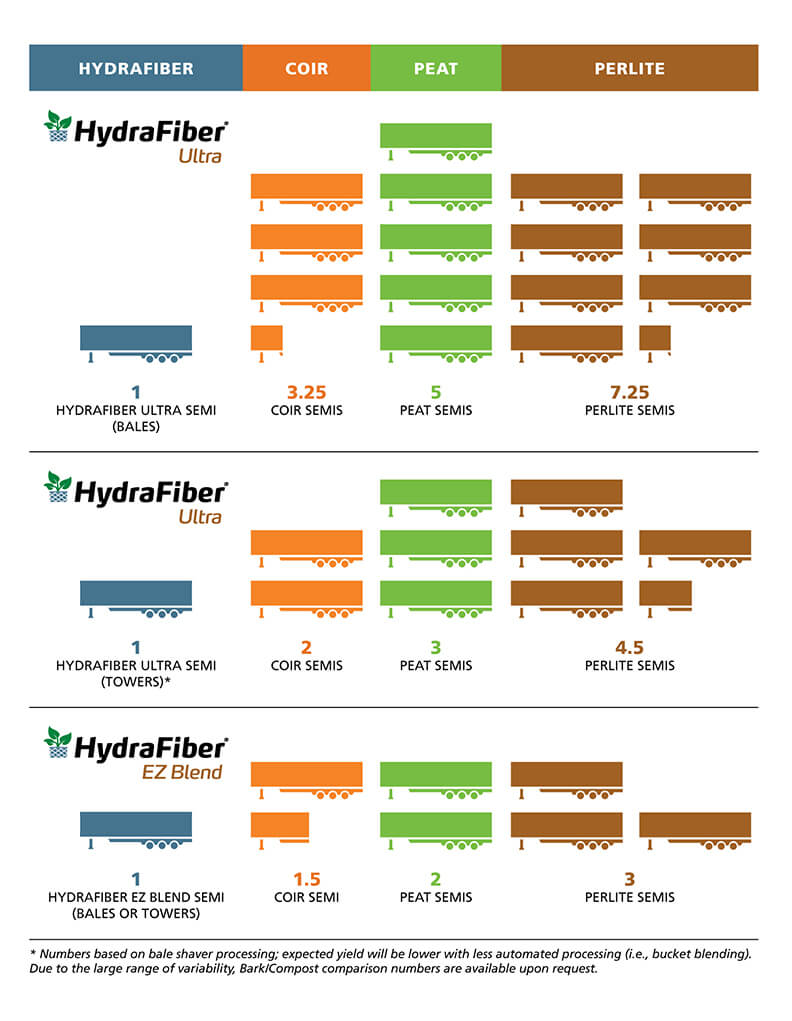

Improved Business Efficiencies

HydraFiber has a low bulk density, and comes highly compressed in both bale and tower form. Because of this, the number of truckloads needed is lower compared to other substrate options – providing you with better freight efficiency, less storage, and lower handling costs.

Better Roots. Better Shelf Life.

"When we made the transition, we had to tweak the filling slightly. Working to get it right is so rewarding when we see the nice root mass that our plants develop. HydraFiber delivers the soil airspace plants need to thrive." - Joe Moore, Head of Operations, Lucas Greenhouses

Growers consistently see better rooting with HydraFiber blends, and that means better shelf life for the plants they grow! Read this case study to see how Lucas Greenhouses dialed in their custom media mix with a finished HydraFiber blend that produced plants that were better prepared for the retail shelf, and customers immediately noticed.

Peat-Lite Mix vs. HydraFiber Mix

Cilantro Production

(Left) Control: Peat-Lite

(Middle) Mix HydraFiber Ultra 065WB: 40%, Peat 60%

(Right) HydraFiber Ultra 065WB: 30%, Peat 70%

Bark Mix vs. HydraFiber Mix

Echeveria Production

(Left) Control: Bark-Based Mix

(Right) HydraFiber Ultra: 160WB 35%, Bark 65%

Peat-Coir Mix vs. HydraFiber Mix

Mum Production

(Left) Control: Coir 50%, Peat 50%

(Right) HydraFiber Ultra 065WB 35%, Coir 65%

HydraFiber Mix

Gaura Propagation

HydraFiber Ultra 160WB 40%, Peat 60%

Peat-Perlite Mix vs. HydraFiber Mix

Coleus Production

(Left) Control: Peat-Perlite Mix

(Right) HydraFiber EZ Blend 50%, Peat 50%

Peat Mix vs. HydraFiber Mix

Hibiscus Production

(Left) Control: Peat Mix

(Right) HydraFiber Ultra 160WB 30%, Peat 70%

HydraFiber Mix

Hemp Production

HydraFiber Ultra 160WB 40%, Peat 60%

HydraFiber Mix

Tomato Production

HydraFiber Ultra 160WB 30%, Peat 70%

Easier Water Uptake

HydraFiber's tremendous surface area makes water work more efficiently. Water is held on the surface of the fiber and is more readily accessible when the plant needs it. To get an up-close-and-personal view of HydraFiber and how it is absorbed by the fiber, check out our Water Uptake Video on HydraFiber, peat and coir particles.

Peat

Peat's waxy cuticle sheds water which doesn't store water for the plant

HydraFiber

HydraFiber Thermally Refined fibers store and release water for the plant

Coir

Coir fibers trap water needed for the plant

Adding 20% HydraFiber to peat increases available water compared to 20% perlite or 20% coir blended with peat

Safe Outdoor Storage

HydraFiber bales and towers are wrapped in plastic, clearly labeled with the formulation name for easy identification. Each pallet receives a pallet cap and is shrink-wrapped. As long as the plastic is not pierced at off-loading, HydraFiber can be safely stored outdoors. In addition, with moisture level standard at approximately 20%, these raw materials do not freeze.